Changzhou Delai Motor Co., Ltd. was established in 2008, mainly producing DC brush motors and gearboxes. We focus on designing and producing products to meet the special needs of our customers. Our products are widely used in automobiles ATM、 Pumps and valves. We have conducted in-depth research on the noise, electromagnetic interference, and lifespan of motors, and our products perform well in these areas. We adopt lean management, quality control, and continuous improvement of our processing technology. We adopt flexible production methods to meet customers' small batches and different requirements, while making every effort to control costs and provide customers with reasonable prices.

2008 2008

established in

40 40

190 190

-

-

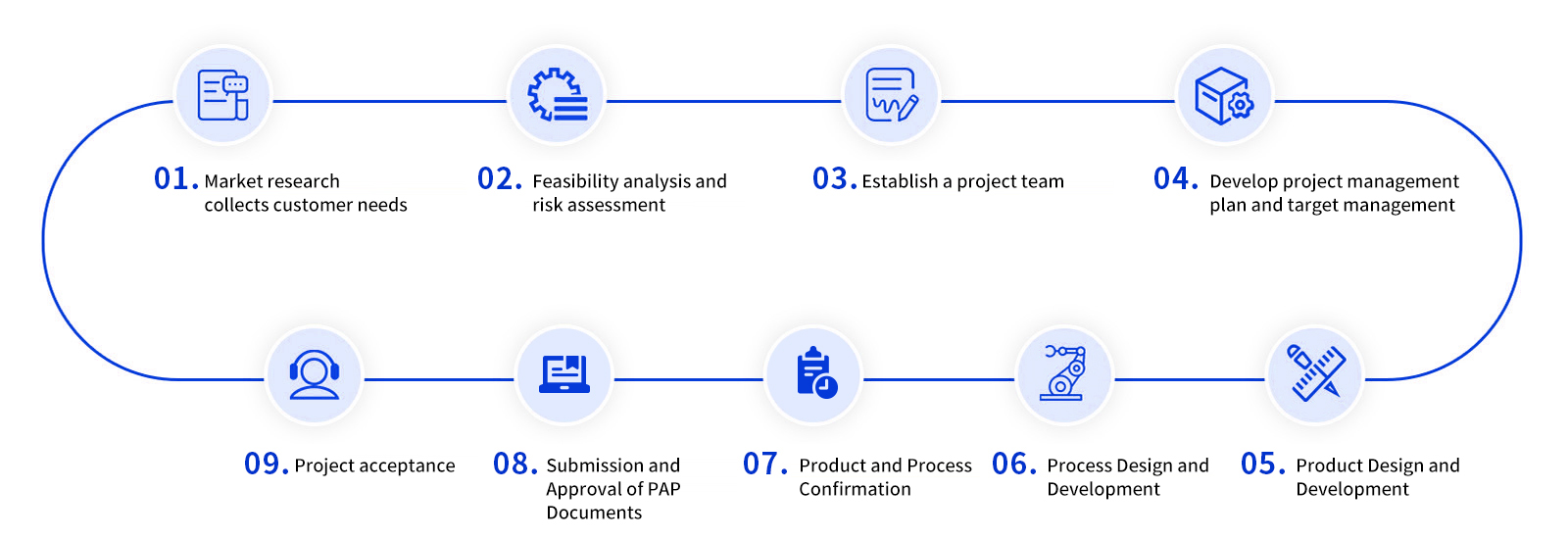

R&D&Design Capability

Follow the IATF16949 project management process

School enterprise cooperation : Our company has launched school enterprise cooperation with multiple universities and colleges such as the Hong Kong University of Science and Technology and Tongji University in Shanghai. Our professional R&D team is led by graduate and doctoral supervisors from the Advanced Materials Science (AMAT) and Quantum Technology Center (QST) of the Hong Kong University of Science and Technology. Our R&D team consists of nearly 15 people, all of whom hold bachelor's degrees or above.

Our company has 2 senior EMC experts in micro motors, dedicated to the research and development of micro motor EMC technology and project development for 16 years. Our products perfectly meet the CISPR25 CLASS5 standard requirements, as well as the EMC standard requirements of Mercedes Benz, BMW, Volvo and other enterprises.

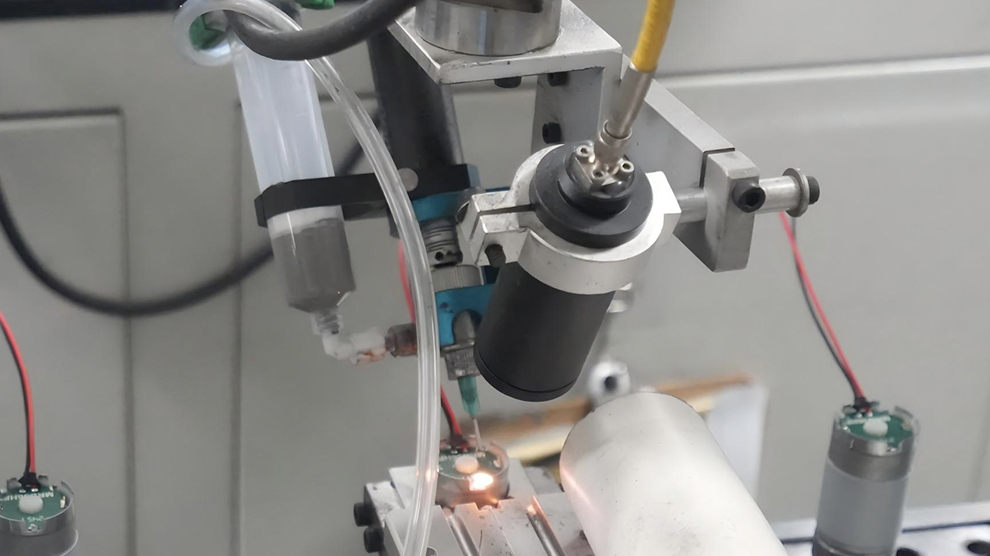

The production chain is interconnected, and quality inspection is crucial

DeLai has strong manufacturing capabilities, introduced MES management system, and automated production lines, effectively improving production flexibility, ensuring product quality, and achieving cost reduction and efficiency improvement.

-

Patent certificate

Patent certificate -

Patent certificate

Patent certificate -

Patent certificate

Patent certificate -

Patent certificate

Patent certificate -

IATF16949:2016

IATF16949:2016 -

ISO45001:2018

ISO45001:2018 -

ISO14001:2015

ISO14001:2015 -

Growth Board of Jiangsu Equity Trading Center Listed

Growth Board of Jiangsu Equity Trading Center Listed -

Qualification Certificate

Qualification Certificate -

Intellectual Property Management System Certification

Intellectual Property Management System Certification -

Advanced enterprise in science and technology innovation, digitalization, and intelligence

Advanced enterprise in science and technology innovation, digitalization, and intelligence